ASTM A572 steel plate is a specification for high-strength low-alloy structural steel plates, designed for structural applications where higher strength is required. A572 steel is commonly used in construction and other structural applications. The specification covers 5 grades of HSLA steel profiles, plates, sheet piling, and bars.

Key Properties:

- Composition: ASTM A572 contains various alloying elements such as carbon, manganese, phosphorus, sulfur, and silicon. It is available in several grades, including Grade 42, 50, 55, 60, and 65, with varying yield and tensile strengths.

- Mechanical Properties:

- Yield Strength: Generally ranges from 290 MPa (42,000 psi) for Grade 42 to 450 MPa (65,000 psi) for Grade 65.

- Tensile Strength: Ranges from 420 MPa (60,000 psi) to 550 MPa (80,000 psi), depending on the specific grade.

Applications:

ASTM A572 steel plates are widely used in:

- Construction of bridges and buildings.

- Structural components in industrial and commercial construction.

- Fabrication of heavy equipment and machinery.

- Low-temperature applications due to its impact resistance.

- Grades 42, 50, 55 are intended for riveted, bolted or welded structurals, Grade 60 and 65 are for riveted and bolted construction of bridges, welded constructions and more applications.

Overall, ASTM A572 steel plates offer a combination of strength, durability, and versatility, making them suitable for a wide variety of structural applications.

Referenced Documents:

ASTM Standards:

- A6/A6M: General requirements for rolled structural steel bars, plates, shapes, and sheet piling

- A36/A36M: Carbon structural steel specification

- A514/A514M: Specification for quenched and tempered alloy steel plate with high yiled strength, suitable for welding

- A588/A588M Specification for High-Strength Low-Alloy Structural STeel, up to 50 ksi [245 MPa] Minimum Yield Point, with Atmospheric Corrosion Resistance

ASTM A572 Grade 50, 60 & 65 Data Sheet Properties

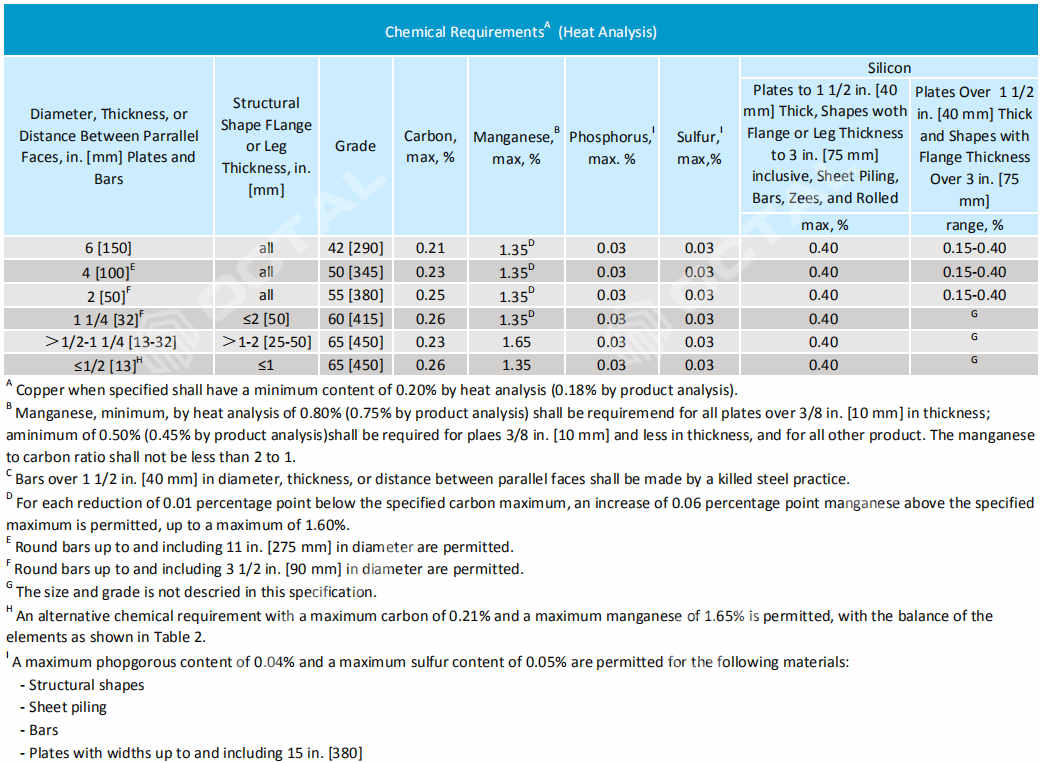

Chemical properties shall conform to the requirements prescribed in Table 2 and Table 3 for alloy elements. Tensile strength and yiled strength shall comply with Table 4.

Chemical Composition

Table 3:

Table 3: Alloy elements composition

Type A | Elements | Heat Analysis, % |

|---|---|---|

1 | Columbium | 0.005-0.05B |

2 | Vanadium | 0.01-0.15C |

3 | Columbium | 0.005-0.05B |

Vandadium | 0.01-0.15C | |

Columbium plus vanadium | 0.02-0.15D | |

5 | Titanium | 0.006-0.04 |

Nitrogen | 0.003-0.015 | |

Vanadium | 0.06 max |

A: Alloy content shall comply with Type 1, 2, 3, or 5 and shall be on test report.

B: Product analysis limits = 0.004 to 0.06%.

C: Product analysis limits = 0.005 to 0.17%.

D: Product analysis limits = 0.01 to 0.16%.

Mechanical Properties

Grade | Yield Point, min | Tensile Strenth, min | Minimum Elongation, % B,C,D | |||

|---|---|---|---|---|---|---|

kis | [MPa] | ksi | [MPa] | in 8 in [200 mm] | in 2 in [200 mm] | |

42 [290] | 42 | [290] | 60 | [415] | 20 | 24 |

50 [345] | 50 | [345] | 65 | [450] | 18 | 21 |

55 [380] | 55 | [380] | 70 | [485] | 17 | 20 |

60 [415] | 60 | [415] | 75 | [520] | 16 | 18 |

65 [450] | 65 | [450] | 80 | [550] | 15 | 17 |

A: Specimen shall comply with Specification of A6/A6M.

B: Elongation not required to be determi ed for floor plate.

C: For wide flange shapesover 426 lb/ft [634 kg/m], elongation in 2 in. [50 mm] of 19% minimum applies.

D: For plates wider than 24 in. [600 mm], the elongation requirement is reduced two percedntage points for Grade 42, 50, and 55 [290,345,and 380], and three percentage points for Grade 60 and 65 [415 and 450]. See elongation requirement asjustments in the Tesion Tests section of Specification A6/A6M.

General Requirements for Delivery

Structural steel plates supplied under ASTM A572 must meet the requirements outlined in the current edition of Specification A6/A6M for the specific structural product ordered, unless there is a conflict, in which case this specification will take precedence.

Coils are not considered applicable to this specification until they are processed into a finished structural product. Structural steel plates produced from coils are those that have been cut to individual lengths from a coil. The processor is directly responsible for the operations involved in transforming a coil into a finished structural product. These operations include decoiling, leveling or straightening, hot-forming or cold-forming (if applicable), cutting to length, testing, inspection, conditioning, heat treatment (if applicable), packing, marking, loading for shipment, and certification.

Our Supply Range:

Description: Carbon Steel ASME SA572/ ASTM A572 Grade C & D

Manufacturing Types: Hot Rolled

Thickness: 2 to 150 mm

Width: 0.6m to 3m

Length: 6m, 12m, customized

Surface: Natural, Painted

Packing: Standard sea packing, bundled with streel strip.