ASTM A516 steel plate is a specification for carbon steel plates intended for use in moderate and lower temperature service. These plates are mainly used in the fabrication of pressure vessels and industrial boilers.

Key Properties:

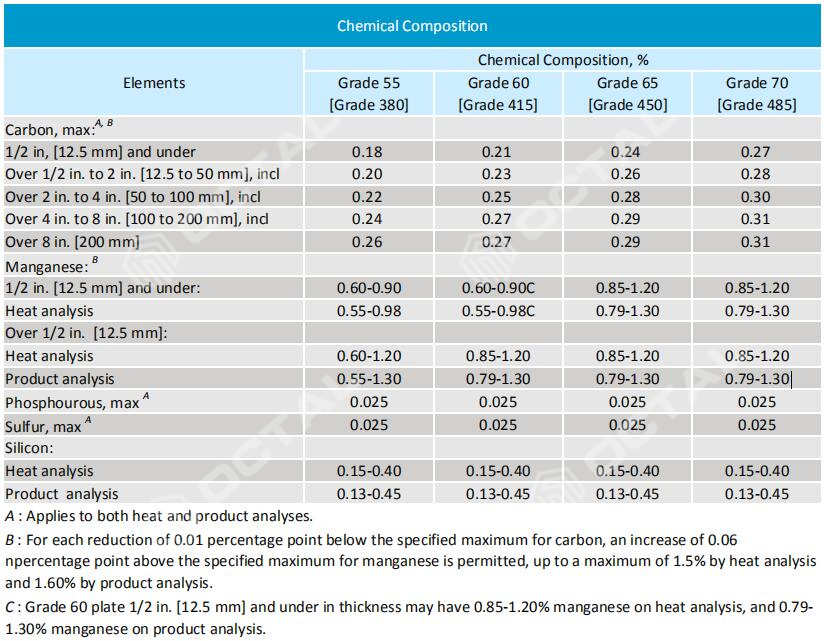

- Composition: ASTM A516 plates typically contain carbon, manganese, phosphorus, sulfur, and silicon. The carbon content generally ranges from 0.26% to 0.30%.

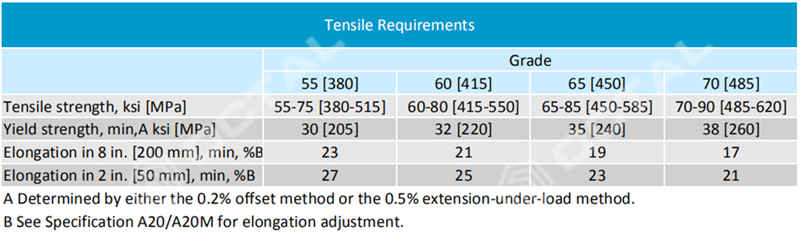

- Mechanical Properties:

- Yield Strength: Ranges from 220 MPa (32,000 psi) to 460 MPa (67,000 psi), depending on the grade (such as Grade 55, 60, 65, and 70).

- Tensile Strength: Ranges from 380 MPa (55,000 psi) to 620 MPa (90,000 psi).

Applications:

ASTM A516 steel plates are commonly used in:

- Fabrication of pressure vessels for the oil, gas, and chemical industries.

- Construction of storage tanks for liquids at moderate temperatures.

- Boilers and heat exchangers in power generation plants.

Overall, ASTM A516 steel plates are essential for applications requiring strength, durability, and good notch toughness in medium to low-temperature environments.

ASTM A516 Grade 70 - Common Use Grade

It is categorized into four grades based on different strength levels: 55, 60, 65, and 70, with Grade 70 being the most commonly used.

Grade | Tensile Strength Ksi [MPa] |

|---|---|

55 [380] | 55-75 |

60 [415] | 60-80 |

65 [450] | 65-85 |

70 [485] | 70-90 |

Maximum Thickness Limited

The maximum thickness of the plates is restricted solely by the ability of the composition to meet the specified mechanical property requirements. For plates manufactured from coils and provided without heat treatment or only with stress relieving, the requirements and test results must comply with A20/A20M. Coils are not considered qualified under this specification until they are cut into plates.

Grade | Maximum Thickness in. [mm] |

|---|---|

55 [380] | 12 [305] |

60 [415] | 8 [205] |

65 [450] | 8 [205] |

70 [485] | 8 [205] |

Referenced Documents:

ASTM standards:

- A20/A20M: General requirements of steel plates for pressure vessels and tanks

- A435/A435M: Specification for straight-beam ultrasonic examination of steel plates

- A577/A577M: For angle-beam ultrasonic examination of steel plates

- A578/A578M: For straight-beam UT examniation of rolled plates for special applications

Materials and Manufacture Details for A516 Plates

The steel shall be killed and shall confirm to the fine austenitic grain size requirement of SPEC A20/A20M.

Heat Treatment

Plates in thickness of 40 mm [1.5 in] or under it normally supplied in as-rolled condition. In case require normalized or stress relieved shall be informed before the order.

Plates over 40 mm [1.5 in] thickness shall be normalized.

In case notch-toughness tests are required on plates 1.5 in [40 mm] and under this thickness, the plates shall be normalized unless otherwise specified by the purchaser.

Agreed by purchaser, cooling rates faster than cooling in air are permissible for improvement of the toughness, provided the plates are subsequently tempered in 1100 to 1300℉ [595 to 705 ℃].

ASTM A516 Grade 70, 65, 60 Material Data Sheet

Chemical Composition

ASTM A516 GR 70 plates shall comply with the chemical requirements to below table 1, unless otherwise modified in accordance with S17 of Vacuum Carbon-Deoxidized Steel in A20/A20M.

Mechanical Properties

Tensile Strength and yield strength shall conform to below Table 2.

Our Supply Range:

Description: Carbon Steel ASTM A516 Grade 70, 65, 60, 55

Manufacturing Types: Hot Rolled

Thickness: 2mm to 150 mm

Width: 0.6m to 3m

Length: 6m, 12m, customized

Surface: Natural, Painted

Packing: Standard sea packing, bundled with streel strip.