Laser-cut metal/steel refers to metal components that have been shaped or modified using laser cutting technology. This process utilizes highly focused laser beams to precisely cut or engrave metal materials into desired shapes and designs. Metal materials mainly types in sheet metal, like carbon steel plate, corten steel plate and stainless steel plate, sheet.

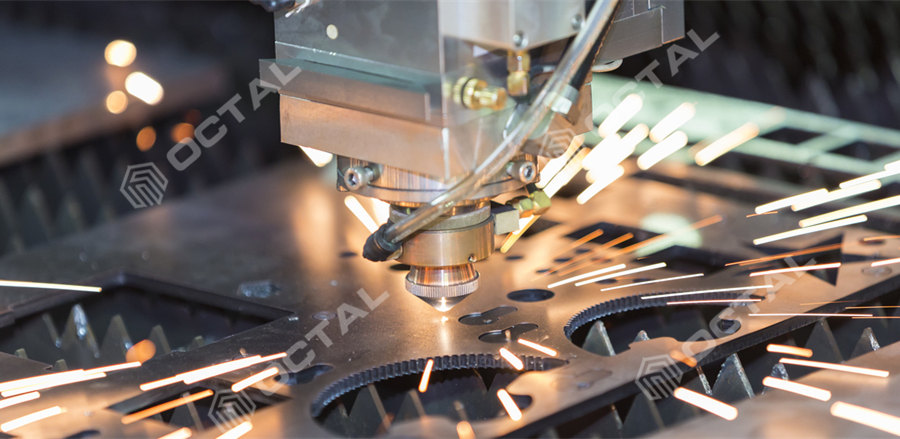

Laser Cutting Process:

- Laser Generation: A laser cutter generates a high-powered laser beam, typically using a solid-state laser, CO2 laser, or fiber laser.

- Focus and Control: The laser beam is focused onto the material's surface, which allows for extremely precise cutting.

- Material Interaction: As the laser beam moves over the material, it melts or vaporizes the metal, creating a clean, efficient cut.

- Assistance Gases: In some cases, assist gases such as oxygen or nitrogen are used to improve cutting speed and quality by blowing away molten metal.

Typical Applications:

Laser-cut metal is widely used in various industries, including:

- Manufacturing: Production of components for machinery, automotive parts, and appliances.

- Construction: Fabrication of structural components such as beams, brackets, and frames.

- Art and Design: Creation of intricate patterns and designs for artistic projects, signage, and decorative elements.

- Aerospace and Defense: Precision cutting for aircraft parts, military equipment, and other high-stakes applications.

laser cut metal steel corten steel stainless steel

What products we can offer by metal laser cutting services

If you are looking for tight tolerances, cutting difficult profiles, high-speed cutting with precision, then laser cutting is your answer. We provide metal laser cutting services, which means we can do customized steel plate, sheet, panels as per the need of the customer for which we use Laser cutting process. Below the laser cut metal products and services we do:

Cutting Thickness

Laser cutting method is best suited for cutting steel plate which has a thickness up to 1.25 inch (36 mm). After one inch, the cutting process will become difficulty and it need to be perfectly set which requires to configure each thing correctly. Like installing the material, checking the nozzle condition, beam quality, and gas purity. We know how to use laser technology to laser cut metal.

Custom Laser Cut Metal Tolerances

For different thickness of steels, different length and width tolerances standard will be applied, and normally as below:

• Steel thickness under 1.0mm, tolerances is +/- 0.12 mm.

• From 1.0 mm to 3.0 mm, tolerances allowed +/- 0.15 mm.

• From 3.0 mm to 6.0 mm, +/- 0.20 mm.

• 6.0 mm to 15.0 mm, laser cutting tolerances at +/- 0.25 mm.

• Up 15.0 mm to 20.0 mm, laser cut tolerances at +/- 0.75 mm.

Laser Cutting Metal Standard and Grades

Cutting Carbon Steel Standard and Grade

• ASTM A36 (S235)

• ASTM A516

• ASTM A537

• ASTM A572

• ASTM A573

• S275

• S355

• SPCC – Cold rolled steel

• EN8

• Galvanized steel

• Tool steel

Laser Cut Stainless Steel Sheet Metal

Stainless steel materials for laser cutting

• ASTM 240 304/304L/S30400/S30403

• ASTM A240 316/316L/316Ti/S31600/S31603

• ASTM A240 321/S32100

• 310S/S31008

• 321/S32100

• Duplex steel

• Inconel Alloy 625, 800, 800H, 825

• Hastelloy steel

For hot rolled and cold rolled stainless steel plate, sheet, profiles.

Laser Cut Corten Steel Plate, Sheet, Metal

• ASTM A242 Grade A, B

• ASTM A588 Grade A, B

• Corten A, Corten B

• Weather Steel Plate